Carbide dies help in increasing productivity simply by reducing the cost and the downtime of replacement tooling. The carbide extruding type of dies have the ability of providing top quality finished product. Especially when the main concern is surface finish requirements and dimensional satisfaction. Specifically designed to increase productivity and minimize wear, carbide dies make one of the most excellent choices for die sets that need to be use extensively. These dies are known for providing satisfactory performance. And they tend to last longer than their steel counterparts that come with a very short life span. The best thing about carbide dies is that they can last for a very long time even when they are use in the most extreme conditions.

carbide rod

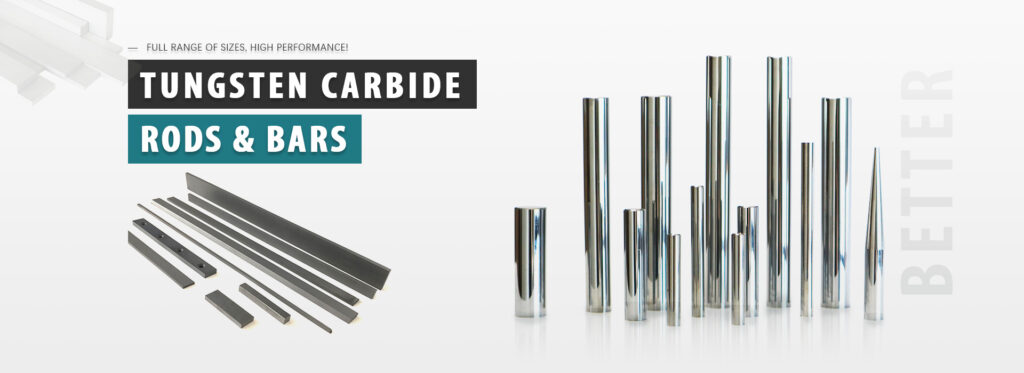

A solid cemented carbide rod is use for top quality carbide tools, like end mills, milling cutters, reamers and drills. Such rods can even be use for measuring stamping and cutting tools and in packaging, paper, non-ferrous processing and printing industries. These rods are not only use for drilling and cutting tools. But even for different toll wore parts, structural materials and input needles. Speaking of tungsten carbide plate, these are specifically make to boost the wear resistance of different components and parts. These plates can be use for fully restoring the dimensions of different parts and components through welding overlay.

Chinese Carbide dies are the foremost choice in drawing wire-industry equipment. When an economical option is desire over better wear resistance and wire-surface finish. It is a little, ultra-hard precision tool with a small hole at its center. It can use for manufacturing long-lasting, high-quality carbide drawing dies for use in making wire, rods, pipe, and bars in all standard shapes-round, hexagonal, and rectangle. These dies can serve various materials, including mild steel, high-carbon steel, stainless steel, and numerous other steel alloys.